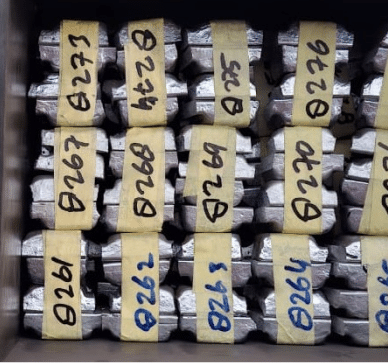

Vedanta adheres to stringent quality standards in every aspect of its business, from the procurement of raw materials to the final delivery of goods to its esteemed clientele. Our well-equipped testing facilities and extensive technical expertise in the manufacture of lead and lead alloy ingots are two of Everest’s strongest suit. We provide our clients with complete access to our wide range of technological services that are tailored to their requirements. Before pouring molten metal into the molds, each batch is examined to guarantee that the alloy’s dross content, grain size, and chemistry are correct. All components are kept under strict control and appropriate documentation is kept.

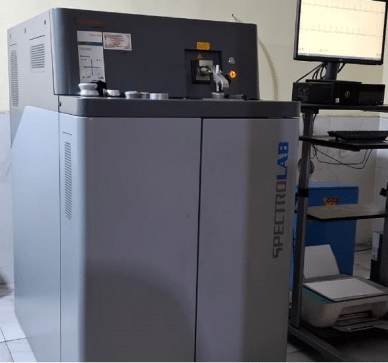

To provide total traceability at a later time, each batch is given a distinct batch number that is also marked on every pertinent ingot. A highly skilled and committed team guarantees total adherence to the strictest standards in addition to in-process inspection. Professionals are involved in every step of the process, from selecting the best raw materials to using a variety of procedures to guarantee the goods meet the highest standards of quality. Vadanta has been investing constantly in process improvement, new technology, and quality control systems due to the growing demand for international standard products and the fierce competition that is rising daily in these markets. SPC procedures are routinely applied to guarantee thorough and in-depth examinations of the many quality measures implemented by officials. According to the standards of the quality standard, an accurate record is kept.

At Vedanta Metal Industries Limited, we utilize cutting-edge instruments to ensure the highest level of precision in our production: